1 Weigao Road,Torch Hight-Tech Industrial Development Zone, Weihai, Shandong Province, China

鲁公网安备 37100302000150号

鲁公网安备 37100302000150号

Follow Us

1 Weigao Road,Torch Hight-Tech Industrial Development Zone, Weihai, Shandong Province, China

鲁公网安备 37100302000150号

鲁公网安备 37100302000150号

Follow Us

Recently, Weigao shares under Weigao Company to achieve 27G ultra-thin-wall, high-throughput, high-strength medical beauty needle mass production, mass delivery, breaking the long-term dependence on imports of this type of needle tip situation, marking Weigao in the high-end needle manufacturing field breakthrough foreign technology monopoly, to reach the industry leading level.

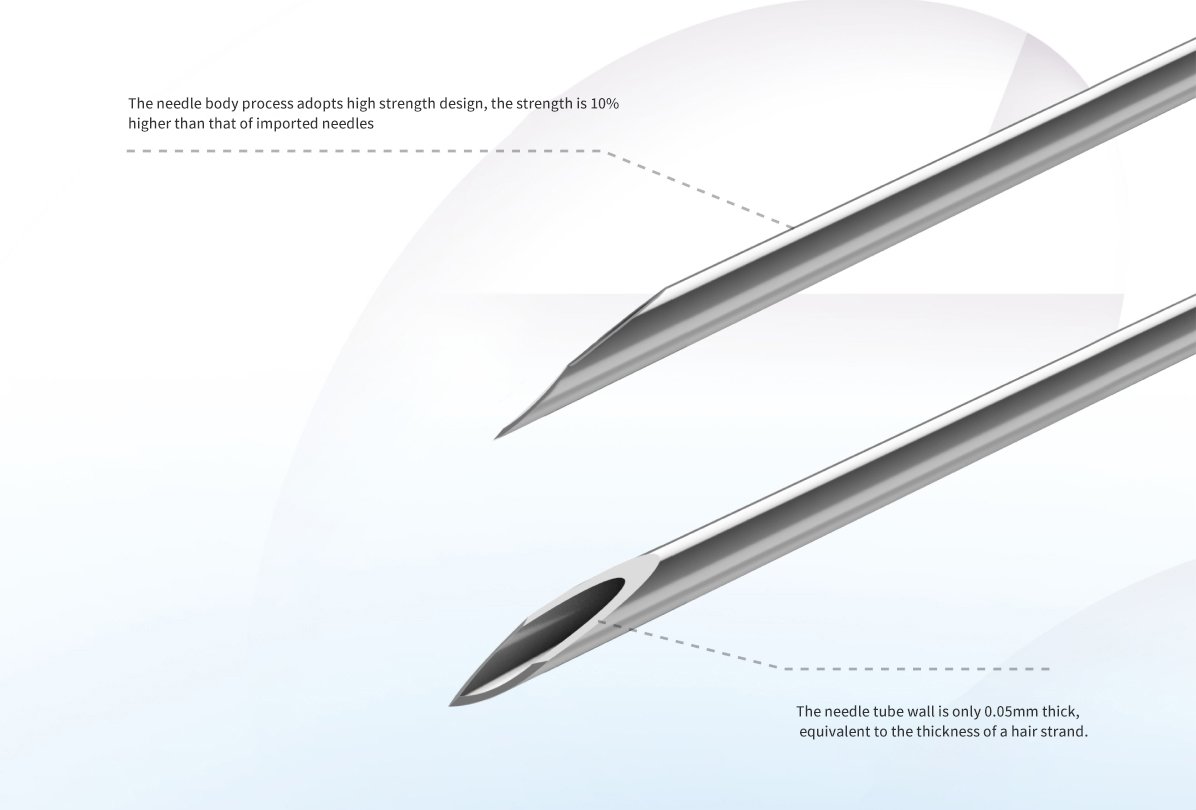

In recent years, medical beauty needles have become an emerging force in the field of medical puncture needles, among which ultra-thin wall and high-strength needle tips are widely favored by the market, and this kind of medical beauty needle with a wall thickness thinner than the hair has significant advantages in clinical practice. Its ultra-thin wall design makes the needle have less resistance and smoother handling feel when inserting into the skin, and the drug flux is significantly higher than that of ordinary needles, which can greatly reduce the pain of patients and improve the use experience.

At the same time, the high strength characteristics ensure that the needle has sufficient durability, stability and safety during use, even in multiple uses or complex situations, the high strength medical beauty needle can maintain its shape and functional integrity, effectively reducing the risk of medical accidents caused by material problems.

At the same time to meet the "ultra-thin wall, high throughput, high strength" of the needle production level is a big challenge, especially this 0.05mm wall thickness of 27G ultra-thin wall needle (the average diameter of the hair is 0.06mm), domestic and foreign peers can achieve stable mass production of only a handful, Witan company in order to achieve this technological breakthrough, invested a lot of resources and energy. The company's technical team through in-depth research on the materials, processes and needle structure of the needle tips used in the medical beauty industry, for clinical use scenarios, the courage to break through conventional thinking, bold trial and error, and continuous innovation, combined with the technical advantages of Japanese experts of Witten Company, actively communicate and cooperate with the same industry at home and abroad, and firmly grasp the two key points of steel strip trace element control and drawing process arrangement. After continuous attempts, the small batch samples successfully obtained customer approval.

Once the small batch samples are approved, the subsequent batch conversion process becomes an important challenge for the production system. This process involves many links and factors, and requires the production system to have efficient, stable and flexible capabilities to ensure the stability of batch conversion.

In this process, the production, technology and quality teams of Witeng Company give full play to the advantages of efficient internal collaboration, whether it is from the conversion of drawings, BOM sets, technical standards solidification, or the formulation of process flow, process inspection, release inspection standards, each system breaks departmental barriers, showing extraordinary team cohesion and centripetal force. With high work efficiency to promote the model of needle smooth batch production, the first batch production of needle has been to the market, subsequent orders have also begun to put into production.

The mass production of ultra-thin-wall, high-throughput, high-strength medical aesthetic needles is of great significance to the medical aesthetic industry, which not only improves the safety and comfort of medical aesthetic surgery, but also brings better treatment experience to patients, and promotes technological progress and material innovation in the medical aesthetic industry, driving the development of the industry.

Looking forward to the future, Witeng will continue to be committed to product development and technological innovation in the field of medical puncture needles, constantly improve the quality and performance of products, continue to actively expand domestic and foreign markets, and provide more patients with high-quality medical puncture products and services. It is believed that with the efforts of Witten Company, the field of Meimei puncture needle will see the application and popularization of more innovative technologies, providing a more refined, safe and efficient solution for medical puncture treatment.